Highly applicable IOT cloud platform

All kinds of equipment can be interconnected and generate value-added services to create unlimited business opportunities, which are well known IOT charm, but in fact, is not easy.

Taking the new technology agriculture as an example, ask a farmer who does not have the knowledge of the ICT background to spend money to build the IOT farm, and then explore the planting technology, and summarize the planting process and engineers to communicate, and continue to support maintenance costs to ensure the correct planting process able to operate in the IOT system, of course, this opportunity is not high.

Equipment connection is not only high cost, but also need to rely on professional engineers. However, the engineers are limited by the professional segment, who cannot be familiar with the details of each industry in progress, customer needs cannot be well considered in every respect, and the establishment of personalized value-added services is not easy.

The above-mentioned outdated integration and business models hamper IOT applications. Imagining the development of personal computers, not from the requirements of the user to improve the skills (learn DOS instructions); but to reduce the operating threshold (such as: operating system window), so that everyone is easy to get started. Similarly, we think that the interconnection of equipments should be as simple as building blocks.

Only IOT system applications can be free to carry out, and is not limited by the engineering thinking to become popular.

Participating in IOT and creating ideas in various fields can become IOT value-added services, and then share, sales, is our purpose of building a cloud integration environment.

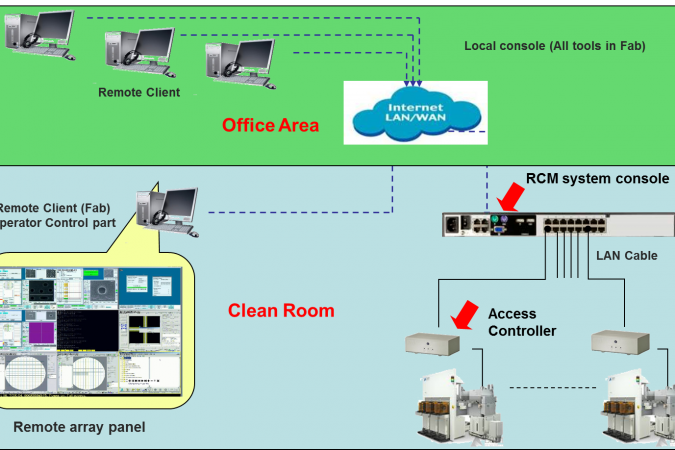

Gathering IOT resources and creativity in the clouds, together with the development of IOT scenario applications, and provide the following services:

-

- Providing fast, simple, economical, combined with commercially available hardware resources for interconnection solutions�.

- Providing a personalized, freelance scenario profile design, trading platform.

- To interactive forums, link market demand, creative ideas, IOT technology, diversified development of affordable IOT services / goods.